Rubber Extrusion Process

Extruded rubber products differ from molded rubber products based on how they’re made. Extruded parts are forced through a die of the required cross section under pressure of an extruder. These parts are often made with soft, unvulcanized rubber compounds that are fed into the extruder. The resulting extrusion leaves the rubber in a soft, pliable state. In this case, the finished extruded products will typically need to be vulcanized, or hardened, before they are rendered usable.

Interested in the rubber extrusion process? Download our Rubber Extrusion Guide to understand the basics of how extruded rubber parts are made for a variety of industry applications.

How Does Rubber Extrusion Work?

The rubber extrusion process begins with a rubber compound being fed into an extruder. The material is fed into a feed hopper, which takes the material and feeds it into various flutes in a revolving screw. The screw will begin to carry the rubber forward into the die, with an increase in pressure and temperature occurring as the material gets closer to the die itself.

Once the material reaches the die, the built-up pressure forces the material through the openings, where it will consequently swell to various degrees based on the material compound and hardness. Because of this tendency toward swelling, many extruded parts require plus or minus tolerances on their cross sections. During vulcanization, the extruded rubber will swell or shrink in both its cross section and its length, depending on the type of rubber compound used.

After vulcanization, a length of rubber extrusion will tend to be reduced in dimension more in the center of the length than in the ends.

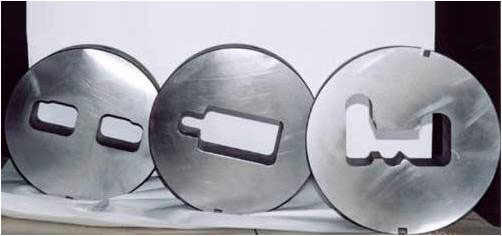

Extrusion Die for Extruded Rubber

An extrusion die is a precise and specific tool made by cutting an opening through a blank of steel. The shape of the opening will match the finished rubber cross section desired for an extruded part. Once in place, the rubber material will be forced through this die via the pressure that builds up from the revolving screw of the extruder.

Many rubber compounds tend to swell when passing through the extrusion die, causing them to experience an increase in dimensions. Thus, each die is made according to each particular part and material to ensure that all tolerances are met for the finished extruded rubber part.

ARPM Standards for Cross Sectional Tolerance Table — Rubber Extrusions

The closer tolerance classes outlined below should not be specified unless required to do so by the final application and they should be restricted to the critical dimensions outlined by the Association for Rubber Products Manufacturers (ARPM) below. The closer tolerances demanded, the tighter the control must be exercised when the material is being extruded and hence the higher the cost incurred. In general, softer materials and those requiring a post cure will need greater tolerances.

| ARPM Class | 1 - High Precision | 2 - Precision | 3 - Commercial | |

|---|---|---|---|---|

| Drawing Designations | E1 | E2 | E3 | |

| Above | Up to | |||

| 0 | 1.5 | ±0.15 | ±0.25 | ±0.40 |

| 1.5 | 2.5 | 0.20 | 0.35 | 0.50 |

| 2.5 | 4.0 | 0.25 | 0.40 | 0.70 |

| 4.0 | 6.3 | 0.35 | 0.50 | 0.80 |

| 6.3 | 10.0 | 0.40 | 0.70 | 1.00 |

| 10.0 | 16.0 | 0.50 | 0.80 | 1.30 |

| 16.0 | 25.0 | 0.70 | 1.00 | 1.60 |

| 25.0 | 40.0 | 0.80 | 1.30 | 2.00 |

| 40.0 | 63.0 | 1.00 | 1.60 | 2.50 |

| 63.0 | 100.0 | 1.30 | 2.00 | 3.20 |

| ARPM Class | 1 - High Precision | 2 - Precision | 3 - Commercial | |

|---|---|---|---|---|

| Drawing Designations | E1 | E2 | E3 | |

| Above | Up to | |||

| 0.00 | 0.06 | ±0.006 | ±0.010 | ±0.015 |

| 0.06 | 0.10 | 0.008 | 0.014 | 0.020 |

| 0.10 | 0.16 | 0.010 | 0.016 | 0.027 |

| 0.16 | 0.25 | 0.014 | 0.020 | 0.031 |

| 0.25 | 0.39 | 0.016 | 0.027 | 0.039 |

| 0.39 | 0.63 | 0.020 | 0.031 | 0.051 |

| 0.63 | 0.98 | 0.027 | 0.039 | 0.063 |

| 0.98 | 1.57 | 0.031 | 0.051 | 0.079 |

| 1.57 | 2.48 | 0.039 | 0.063 | 0.098 |

| 2.48 | 3.94 | 0.051 | 0.079 | 0.126 |

Rubber Extrusion Advantages

There are many advantages to the rubber extrusion process, including:

- Variety of shapes available

- Efficient and economical

- Flexible and lightweight products

- Minimal waste

Extruded Rubber Products

Timco can also cut custom rubber extrusions in a range of lengths, shapes, and rubber compounds to meet various temperature, weather, and technical specifications. Some of them, such as EPDM or neoprene, can be extruded like dense rubber or sponge rubber. Common extruded rubber products include:

- Connectors

- Tubing

- Mandrel formed hoses

- Door, cabinet and window seals

- Vibration reducers

- Gaskets

- Spliced gaskets

- Window seals for mass transit

- Pressure switch square tubing

Interested in extruded rubber products?

Call 1-888-745-7296 or complete our online form to request a quote.

Download our Rubber Extrusion Guide for more information on the rubber extrusion process.