Nitrile Butadiene (NBR) Material Manufacturer

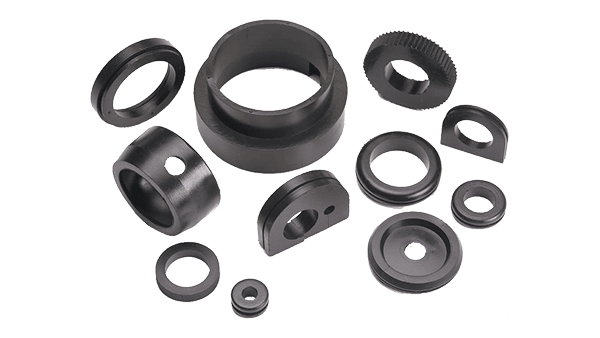

Seals, O-Rings & Gaskets & More

Nitrile rubber is a synthetic rubber that provides excellent resistance to petroleum-based oils as well as mineral and vegetable oil. Timco Rubber can work with your business to design and provide nitrile seals, NBR o-rings, and other parts customized for the specific needs of your applications.

Nitrile Rubber: A Material Made for Oil Resistance

Unlike natural rubber and other materials, nitrile gaskets and other parts are more resistant to heat aging. This feature is a key advantage, as it allows nitrile to not harden and lose its damping capability as quickly as natural rubber and other solutions. Nitrile rubber is also a great material choice for applications that require abrasion resistance and metal adhesion.

Due to its versatility and strong resistances, nitrile material is used in applications involving not only oil, fuel, and chemical resistance, but also those that require resistance to heat, abrasion, water, and gas permeability. From oil rigs to bowling alleys, nitrile rubber can be the right material for your application.

Timco works with a wide variety of companies to provide custom molded and die cut nitrile parts with demanding physical properties. Whether you call them Buna-N seals, NBR o-rings, or something else, our team can design and provide the best, most cost-effective custom molded or die cut parts for your applications.

What is Nitrile (NBR)?

NBR – also called nitrile-butadiene rubber, NBR rubber, and Buna-N – has been an effective rubber material option for a long time. Nitrile was first developed by BASF and Bayer in 1931, with commercial production starting four years later in 1935.

Nitrile is a synthetic rubber copolymer that is created when acrylonitrile (ACN) and butadiene are bonded together using polymerization. NBR can be made with varying levels of acrylonitrile, with higher CAN content providing added resistance to hydrocarbon oils and lower CAN content providing improved flexibility.

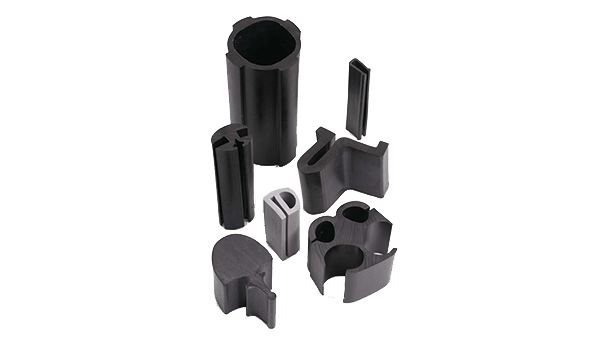

After the polymerization process, NBR is formed into a sheet rubber. The sheet rubber goes through vulcanization with different ingredients to improve certain performance qualities like elasticity, puncture resistance, and more. The resulting compound can then be die cut, extruded, or manufactured some other way into a variety of parts, such as seals and o-rings.

Nitrile Properties

- Common Name: Buna-N, Nitrile, NBR

- ASTM D-2000 Classification: BF, BG, BK

- Chemical Definition: Butadiene Acrylonitrile

- Resistance

- Oil Resistance: Good to Excellent

- Abrasion Resistance: Excellent

- Tear Resistance: Good

- Resistance: Good to Excellent

- Aging Weather/Sunlight: Poor

- Tensile Strength

- Tensile Range (P.S.I): 200-3000

- Elongation (Max %): 600

- Temperature Range

- Low Temperature Usage: -30°F to -40°F | -34°C to -40 °C

- High Temperature Usage: Up to 250°F | 121°C

- Durometer (Hardness) – Range: 20-95 Shore A

- General Characteristics

- Adhesion to Metals: Good to Excellent

- Compression Set: Good

- Resilience/ Rebound: Good

Nitrile Applications

Automotive Industry

- Gaskets

- Seals

- O-rings

- Carburetor and fuel pump diaphragms

- Fuel systems

- Hydraulic hoses

- Tubing

Bowling Industry

- Bowling pin setters

- Roller bumpers

- Anything that comes into direct contact with lane oil

Oil & Gas Industry

- Seals

- Tubing

- Molded shapes

- Rubber-to-metal bonded components

- Connectors

- (BOP) Blowout preventers

- Stripper rubber

- Rotating heads

Nitrile Benefits & Advantages

- Resistance to oil and petroleum products.

- Excellent solution for sealing applications, as Nitrile can stretch without losing shape and resist tearing.

- Good compression set.

- Resistance to abrasion, punctures, and tears.

- Resistance to higher temperatures.

- Resistance to abrasion.

- Resistance to water.

- Resistance to gas permeability.

- Can be compounded for service of temperatures up to 250°F (121°C).

Timco: Your Go-To Supplier of Nitrile Parts

When your applications need more than basic Nitrile parts, it’s crucial to invest in solutions tailored to your performance and design needs. Nitrile can be formulated and manufactured in a variety of ways. Timco works closely with your business to supply you with custom Nitrile PVC parts necessary for your applications.

Timco has delivered high-quality parts and customer service since 1956. Our experts conduct comprehensive engineering reviews to analyze your specific part needs. We help you identify any challenges and opportunities to deliver the best, most cost-effective part solution for all your needs. Our value extends beyond part supply as well, as we offer several services to help your business save valuable time and money:

- Subassembly of rubber parts

- Kanban replenishment

- Kit assembly

- Flexible control methods

- Our in-house stocking program and on-time delivery

Want to make sure that Timco is the right partner for all your Nitrile part requirements?

Nitrile Rubber FAQs

Q: What is nitrile rubber?

A: Nitrile Rubber (NBR) is a synthetic rubber made from the copolymerization of acrylonitrile and butadiene. It is widely known for its superior oil and chemical resistance, making it ideal for demanding industrial applications.

Q: What is the primary characteristic of nitrile rubber?

A: Nitrile Rubber is regarded highly for its excellent resistance to oils, greases, and a wide range of hydrocarbons, along with physical durability. These qualities make it particularly useful in environments where exposure to these substances or regular wear is common.

Q: What other properties does nitrile rubber possess?

A: In addition to oil resistance, NBR also offers good resistance to many solvents and fairly high heat resistance. However, nitrile is prone to ozone cracking and struggles when directly exposed to the outdoors.

Q: What are the most common applications of nitrile rubber?

A: Nitrile rubber is extensively used in the automotive industry for seals, gaskets, hoses, and fuel lines due to its oil resistance. It is also commonly found in applications where exposure to greases and fuels is frequent, ranging from the oil and gas market to the bowling industry.

Q: What are other notable applications of nitrile rubber?

A: In addition to automotive uses, NBR is found in a variety of industries, including:

- Aerospace: Seals, gaskets, and diaphragms.

- Industrial Manufacturing: Gloves, boots, conveyor belts, and O-rings.

- Oil and Gas: Seals, gaskets, hoses, and fuel components.

- Food Processing: Seals and gaskets that meet hygiene and safety standards.

Q: How are nitrile rubber grades classified?

Nitrile rubber grades are typically classified based on the acrylonitrile content, which affects the material’s properties, including oil resistance, flexibility, and low-temperature performance.

Q: How does acrylonitrile content affect nitrile rubber properties?

Higher acrylonitrile content generally improves oil and fuel resistance at the expense of reduced flexibility and performance at lower temperatures. The optimal balance depends on the specific application and environmental conditions.

Q: What are the common processing methods for nitrile rubber?

Nitrile rubber can be processed using various methods, including:

- Extrusion: For producing continuous shapes like seals and gaskets.

- Molding: For creating complex shapes and custom components.

- Calendering: For producing thin sheets and films, often used in coatings or linings.

Interested in Buna-N O-Rings, seals, and other parts for your application?

Get a quote, contact us, or call 1-888-754-5136 to find out more.

Not sure which material you need for your custom rubber product? View our rubber material selection guide.