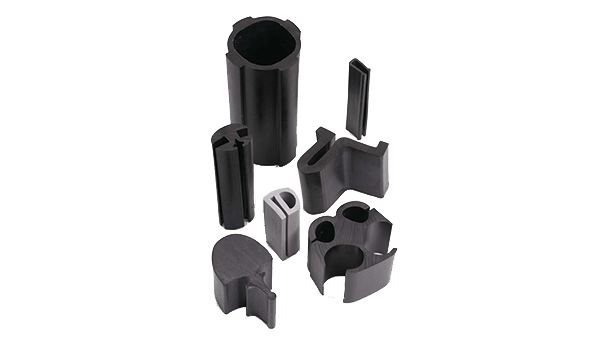

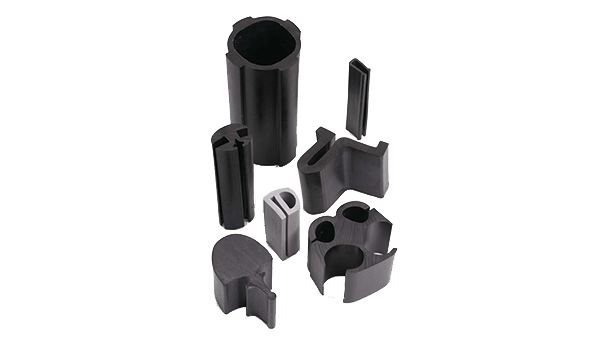

Neoprene Rubber Material Manufacturer

Gaskets, Seals, Tubing & More

From foam to solid sheets, neoprene rubber is a multipurpose elastomer that fits a wide variety of products thanks to benefits like oil and ozone resistance. Timco Rubber specializes in providing neoprene gaskets, seals, o-rings, and other parts for businesses in need of custom solutions for their applications.

What is Neoprene Rubber: A Solution for Oil and Ozone Resistance

Neoprene Rubber, also known as polychloroprene or PC Rubber, is an extremely versatile synthetic rubber offering oil, petroleum, and weathering resistance. These characteristics make neoprene a natural fit for the automotive world, where neoprene rubber applications are used for many exposed parts that can encounter oil or petroleum.

Neoprene’s resistances to both oil and weathering also make it a good fit for several other industries that require a reasonably priced, mid-performance polymer with a good all-around balance of performance properties. In addition to oil and weathering resistance, neoprene’s high tensile strength and low compression set make it a very attractive synthetic rubber for outdoor applications such as custom gaskets and seals. Thanks to these factors, a variety of markets can benefit from neoprene, including the mass transit, wire and cable, food preparation, and construction industries.

Neoprene Properties

- Common Name: Neoprene

- ASTM D-2000 Classification: BC, BE

- Military (MIL-STD 417): SC

- Chemical Definition: Polychloroprene

- Resistance

- Abrasion Resistance: Excellent

- Tear Resistance: Good

- Solvent Resistance: Fair

- Oil Resistance: Fair

- Aging Weather / Sunlight: Good

- Durometer (Hardness): Range 30-90 Shore A

- General Characteristics

- Tensile Range (P.S.I): 500-3000

- Elongation (Max %): 600

- Compression Set: Good

- Resilience /Rebound: Excellent

- Adhesion to Metals: Good to Excellent

- Temperature Range

- Low Temperature Usage: 10° to -50 F° | -12° to -46 C°

- High Temperature Usage: Up to 250 F° | Up to 121 C°

Neoprene Applications

Mass Transit Industry

- Window seals with a locking strip (window and door seal extrusions)

- Door and sensitive door seals

Automotive Industry

- Neoprene Hose Covers

- CVJ boots

- Power transmission belts

- Vibration mounts

- Shock absorber seals

- Breaking and steering system components

Construction Industry

- Window seals

- Window gaskets

- Highway and bridge seals

- Bridge bearing pads

- Washers

- Bridge stay-cable anchor components

- Deviator pads

- O-Rings

- Elevator astragals

Wire and Cable Industry

- Cable jackets

- Jacketing in lead press cured mining cables

- Jacketing in heavy-duty cables

Neoprene Benefits & Advantages

- Outstanding physical toughness

- Resistance to heat and hydrocarbon oils

- Resistance to the degradation effects of sun, ozone, and weather

- Wider short and long-term operating temperature range than other general-purpose hydrocarbon elastomers

- Better flame retardant/self-extinguishing characteristics than exclusively hydrocarbon-based elastomers

- Can meet the stringent Smoke-Flame-Toxicity requirements by the mass transit industry

- Can be certified to the following:

- ASTM E162 (Surface Flammability)

- SMP800C (Toxic Gas Generation)

- ASTM C1166 (Flame Propagation)

- Outstanding resistance to damage caused by twisting and flexing

- Compoundability: Neoprene's polymer structure can be modified to create a material compound with a wide range of chemical and physical properties

Neoprene Rubber FAQs

Q: What is neoprene rubber and what are its primary applications?

Neoprene Rubber is a synthetic rubber developed by DuPont in the 1930s. It's known for its versatility and is widely used in applications such as automotive parts, electrical insulation, and construction seals.

Q: What are the key properties of neoprene rubber?

Neoprene offers excellent chemical stability and good resistance to oils, solvents, and weathering. It maintains flexibility over a wide temperature range, provides good abrasion resistance, and has moderate flame resistance. Additionally, it exhibits good cushioning and vibration dampening properties.

Q: How does neoprene rubber compare to other types of rubber like EPDM or silicone?

Neoprene has better oil and chemical resistance compared to EPDM, but may not match EPDM's superior weathering resistance. Silicone rubber typically offers higher temperature resistance and greater flexibility at low temperatures, whereas neoprene provides better mechanical properties and durability in many industrial applications.

Q: What are the advantages and disadvantages of using neoprene rubber?

- Advantages:

- Excellent resistance to weathering and intermittent exposure to oils and chemicals

- Good mechanical properties and durability

- Ability to be modified to match different chemical or physical needs.

- Moderate flame resistance

- Disadvantages:

- Generally more expensive than some other rubbers

- Can be less flexible at very low temperatures compared to other elastomers

- Limited resistance to certain solvents and hydrocarbons

Q: How is neoprene rubber used in the automotive industry?

Neoprene is utilized for many parts in the automotive sector, including making hoses, belts, gaskets, seals, vibration mounts, and insulation for electrical components. Its resistance to oils and chemicals makes it ideal for parts exposed to engine fluids and varying environmental conditions.

Q: What is the typical lifespan of neoprene rubber products?

The lifespan of neoprene products varies based on usage and environmental conditions. Generally, neoprene rubber can last between 10 to 20 years when properly maintained, although environmental conditions and frequency of use can affect that estimate.

Q: How should neoprene rubber be maintained to ensure longevity?

Maintenance Tips:

- Clean with fresh water after exposure to oils, chemicals, or other harmful substances

- Avoid prolonged exposure to direct sunlight and excessive heat when possible

- Store in a cool, dry place away from sharp objects

- Inspect regularly for signs of wear, cracks, or deterioration and repair as needed

Q: Can neoprene rubber be recycled, and if so, how?

Yes, neoprene can be recycled at an appropriate facility. Recycling processes typically involve shredding the rubber into small particles, which can then be repurposed into products like automotive parts and other rubber goods. Some advanced recycling methods involve chemical processes to break down neoprene into its original monomers for repolymerization.

Interested in neoprene seals, o-rings, and gaskets for your application?

Call 1-888-759-6192 to find out more, or get a quote.

Not sure which material you need for your custom rubber product? View our rubber material selection guide.

Want to make sure that Timco is the right partner for all your Neoprene part requirements?