When you need a part that can bounce back to its original shape after being compressed, some materials are better options than others. A material’s compression set measures just how well a rubber or performance plastic can recover from sustained compression – the worse the set, the more likely that material will be permanently deformed.

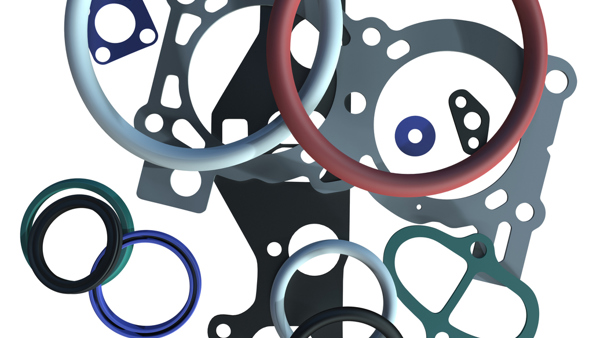

This ability to compress when needed is critical for the long-term success of many parts, including seals, gaskets, and other cushioning elements. Let’s break down the compression set for different rubbers and performance plastics, along with other characteristics that may benefit your application.

How is Compression Set Measured?

Compression set is normally measured through standardized tests that simulate realistic conditions that your parts may face. The most common example of this involves taking a part and compressing it to a specified percentage of its original thickness and exposing it to an elevated temperature. That part is then kept like that for a set amount of time before being released and measured.

In general, businesses follow two international standards to define compression set testing – ASTM D395 and ISO 815. These standards help maintain consistency so that it’s easier for people to evaluate specific materials.

In terms of the actual numbers, compression set is calculated as a percentage – the lower the compression set, the better a material will rebound to its original shape. For example, a compression set of 20% means that material will rebound back to 80% of its original thickness. Each percentage is calculated using the following formula.

- Compression Set (%) = (Original thickness - final thickness) × 100

The ideal percentage is heavily dependent on your application. Some parts can allow for more give, while other applications need to minimize deformation as much as possible. Compression sets of less than 25% can be adequate for various sealing applications, while some high-performance materials may boast sets of 5% or less.

Which Rubber and Plastic Materials are Best for Compression Set?

One of the challenges of compression is that each material doesn’t have an exact percentage. Different formulations can affect just how much a part can rebound, but you can get a general idea for which materials are better suited for compression than others. Here are how different rubber and performance plastic stack up compare to each other.

Excellent

- Natural rubber

Good

- EPDM

- Silicone

- Neoprene

- Nitrile

- Viton

Fair/Poor

- Butyl

- TPE

- PVC

Invest in Parts That Match Your Compression Requirements

Figuring out the best, most cost-effective solution for your parts isn’t easy, and that’s why we’re here to help. We work with you to provide a wide range of options that address your exact specifications, including identifying materials with ideal compression sets. Give us a call at 800-969-6242 or contact us online to invest in quality custom part solutions that address your design needs.