SCAQMD is the air pollution control agency for all of Orange County and the urban portions of Los Angeles, Riverside and San Bernardino counties. It was created by the California legislature to facilitate compliance with the Environmental Protection Agency’s health-based air quality standards that are developed under the federal Clean Air Act. SCAQMD Rule 1111 is one such a standard. Rule 1111 focus is on natural gas-fired, fantype central furnaces, requiring either single-phase or three-phase electric supply, used for comfort heating with a rated heat input capacity of less than 175,000 BTU per hour or for combination gas heating and cooling units with a cooling rate of less than 65,000 BTU per hour. In its latest form Rule 1111 is requiring NOx emissions of these appliances to be less than 14ng/J (Nanograms of NOx / Joule of useful heat delivered to the heated space). The complete rule may be found with the provided link; http://www.aqmd.gov/docs/default-source/rule-book/reg-xi/rule-1111.pdf?sfvrsn=4

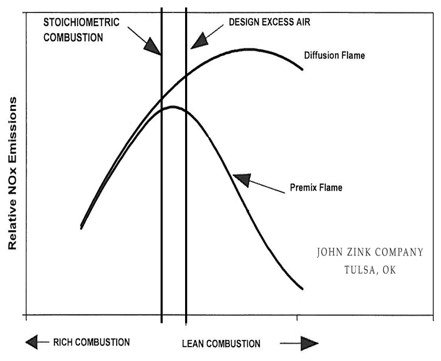

Oxides of nitrogen (NOx) can be formed when O2 and N2 are together under high temperatures as is the case with the combustion of natural gas. It has been shown that NOx contributes to the development of ground-level ozone, fine particulate matter, poor visibility, and acid rain. NOx formation is reduced when the combustion temperature is lower. Many combustion technologies can provide reduced combustion temperatures for this purpose, but one characteristic is present is many of these technologies. It is premixing the air and fuel and combusting them in a lean environment. Having the required air (oxygen) available and in abundance allows the combustion process to proceed quickly, completely and cooler than standard diffusion flames found on most natural gas furnaces built today. The premix flame is short and intense. Premix burners typically have a larger flame holding surface that also add pressure drop to the system.

How does Timco Rubber fit into the NOx equation? To maintain control of the combustion air for implementation of the Low NOx combustion technologies, the burner and heat exchanger systems have to be sealed well. This is especially critical for systems operating under a negative pressure. Any leak in the negative pressure burner or heat exchanger will alter the fuel to air ratio and change the NOx performance of the system. For induced draft systems, sealing of the inducer inlet and shaft are important to maintain combustion air performance and stability. As mentioned the premix flame is short and intense so in some applications additional heat shielding is required to help move the heat release to surfaces away from the flame holding surface. Timco Rubber has the materials and expertise to assist in the sealing and shielding required for premix Low NOx burner and heat exchanger applications. Please contact us today to find out how our expert team of “value adders” can assist you in meeting your specialized needs!

Written By: Bill Roy PE, CGE